Anycubic Water Washable Resin – 1kg

- No Alcohol Needed, User-Friendly

- Low Viscosity, Fast Printing

- Test Approval, No Cracks

- Wide Compatibility

Out of stock

₨ 12,000

ANYCUBIC Water Washable 3D Printer Resin, 405nm High Precision UV-Curing 3D Resin, Low Shrinkage Standard Photopolymer Resin for 8K 12K Capable LCD DLP Resin 3D Printer – 1kg

Features of Anycubic 405nm water washable resin:

- [𝐒𝐮𝐩𝐞𝐫 𝐄𝐚𝐬𝐲 𝐭𝐨 𝐂𝐥𝐞𝐚𝐧] Anycubic Water Washable Resin contains hydrophilic groups with good water solubility, which is can be directly cleaned with water instead of alcohol and greatly save the cost of alcohol use. Besides, it can also be cleaned by Anycubic Wash and Cure Machine or ultrasonic cleaning.

- [𝐇𝐢𝐠𝐡 𝐏𝐫𝐞𝐜𝐢𝐬𝐢𝐨𝐧 𝐚𝐧𝐝 𝐋𝐨𝐰 𝐒𝐡𝐫𝐢𝐧𝐤𝐚𝐠𝐞] Anycubic UV resin prints the models with low shrinkage during the photo curing process, which ensures the high precision and smooth surface. The low shrinkage rate ensures that every model is printed in good details.

- [𝐋𝐨𝐰 𝐎𝐝𝐨𝐫 𝐚𝐧𝐝 𝐒𝐚𝐟𝐞] Anycubic water washable photopolymer resin has low odor and it can ensure customers with a better printing experience. Take a full shake before use in order to have a fully mix the functional components and fully mix the color paste in the resin. Otherwise, uneven coloring of the print may occur.

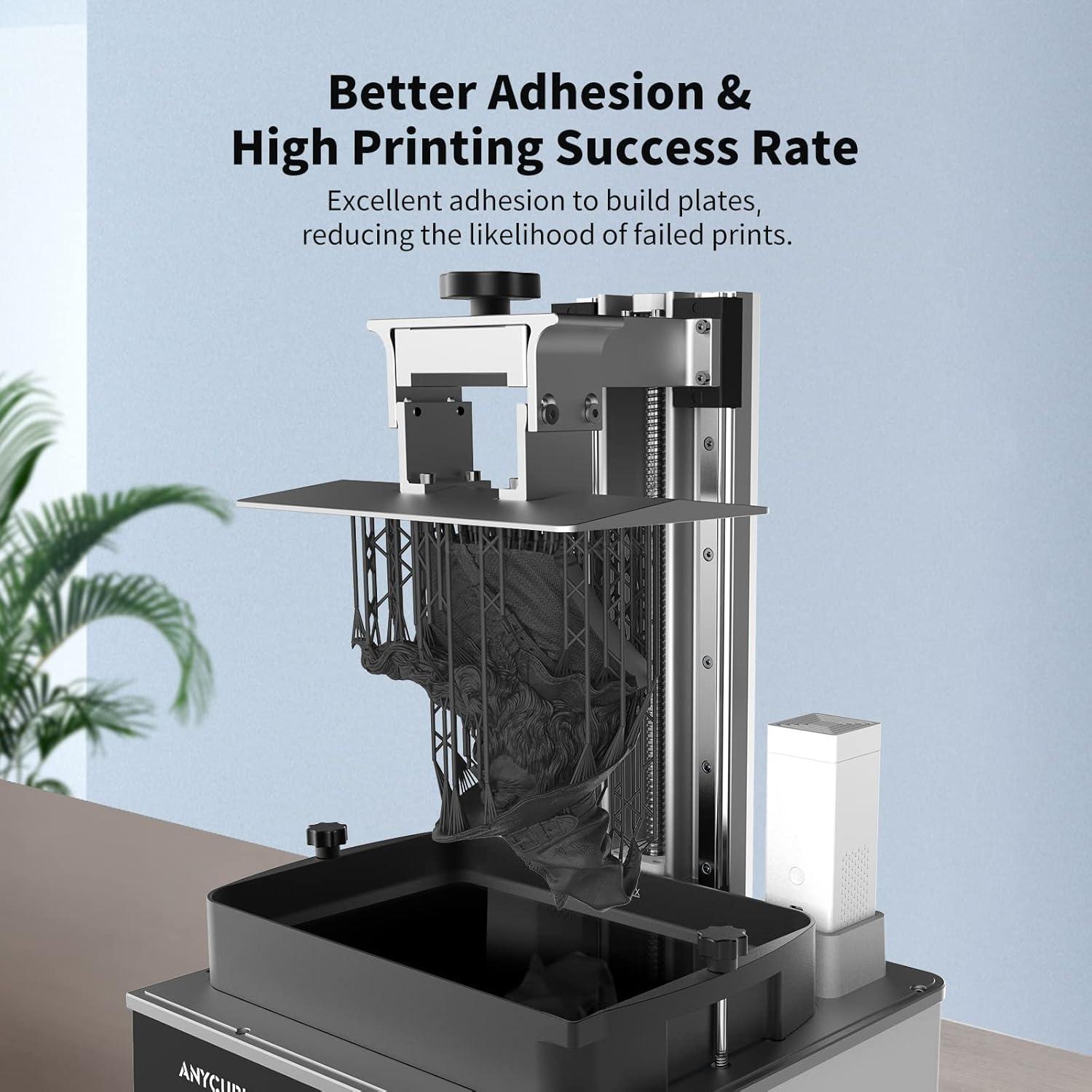

- [𝐋𝐨𝐰 𝐕𝐢𝐬𝐜𝐨𝐬𝐢𝐭𝐲 𝐚𝐧𝐝 𝐆𝐨𝐨𝐝 𝐅𝐥𝐮𝐢𝐝𝐢𝐭𝐲] Low resin viscosity means good fluidity in the printing process, which greatly improves the printing success rate. Anycubic upgraded water washable resin has a longer shelf life to 1 and a half years to help the resin to store longer and safe use.

- [𝐖𝐢𝐝𝐞 𝐂𝐨𝐦𝐩𝐚𝐭𝐢𝐛𝐢𝐥𝐢𝐭𝐲] Compatible with 365-405nm wide band, Anycubic resin is suitable for all 3D LCD/DLP printers on the market, better effect with ANYCUBIC LCD 3D printers.

Instructions for Use:

(1) Before use: Shake the liquid resin before use;Clean the resin tank and the molding platform to keep the bottom of the resin tank in light transmission.

(2) When using: Unscrew the cap and add it to the resin tank according to the equipment requirements;Select the correct print parameters and settings for printing.

(3) After use: After printing, please use the matching tools for post-processing, including blade, diagonal pliers, tweezers, containers, gloves, ethanol(≥95%), lactate or isopropyl alcohol cleaning solution;

(4) Post-processing steps:

A. Remove the printed model from the molding platform with a blade;

B. Submerge the model in the cleaning solution, rinsed or ultrasonically washed, then taken out and drained; ANYCUBlC Wash and Cure machines are suggested to ensure better effect.

C.Proper processing, such as removing support, polishing, coloring, etc.

Precautions:

- The ideal condition for storing uncured resin is a cool, dark place at room temperature and protect from light to avoid high temperature or sunlight.

- Suggested operating temperature is 18-35°C, and a low temperature may affect the printing effect, thus, the resin can be properly preheated before use (not more than 60°C).

- If the resin pigment settles, it can be used after stirring or shaking.

- In order to ensure the performance of the resin, please take out the model in time after cleaning to avoid the model soaking in water for a long time.

- To ensure the mechanical properties of the model, please perform post-curing in time after cleaning and drying.

- To ensure the ideal performance of the curable material, it is necessary to control the intensity and time of the light source after curing. Therefore, the following steps are recommended:

- The intensity of mercury lamp or Led light source is 5-10mW/m?, and the duration is no more than 1 hour (self-regulation);

- The exposure time in the sun (summer) is around 1 hour;

- Proximity or long-term exposure under strong light sources such as high-power high-pressure mercury lamps is prohibited.

- lt is recommended to print in a dark room or be covered with a lid while printing as resin is a photosensitive

material.

| color | Grey, White |

|---|

- Wavelength range for polymerization: 355-410 nm (nanometers)

- Shrink ratio: 3.74-4.24%

- Tensile strength: 59 – 70 Mpa

- Elongation at break: 11-20%

- Shore hardness of fully cured polymer: 84 D

- Viscosity (25℃): 300 mPas

- Density: 1.05-1.25 g/cm3

- Print Layer Thickness: from 35 microns

- Recommended baking time for layers: 6-10 seconds

- Volume: 1 liter