Elegoo Orange Storm Giga Size FDM 3D Printer

- Gigantic Build Volume: 800mm x 800mm x 1000mm

- Efficient Heated Bed

- Fast Printing

- Support Multi-Nozzle Printing

- Powerful Cooling Fan

Available on backorder

₨ 2,500,000

Available on backorder

Elegoo Orange Storm Giga Size FDM 3D Printer

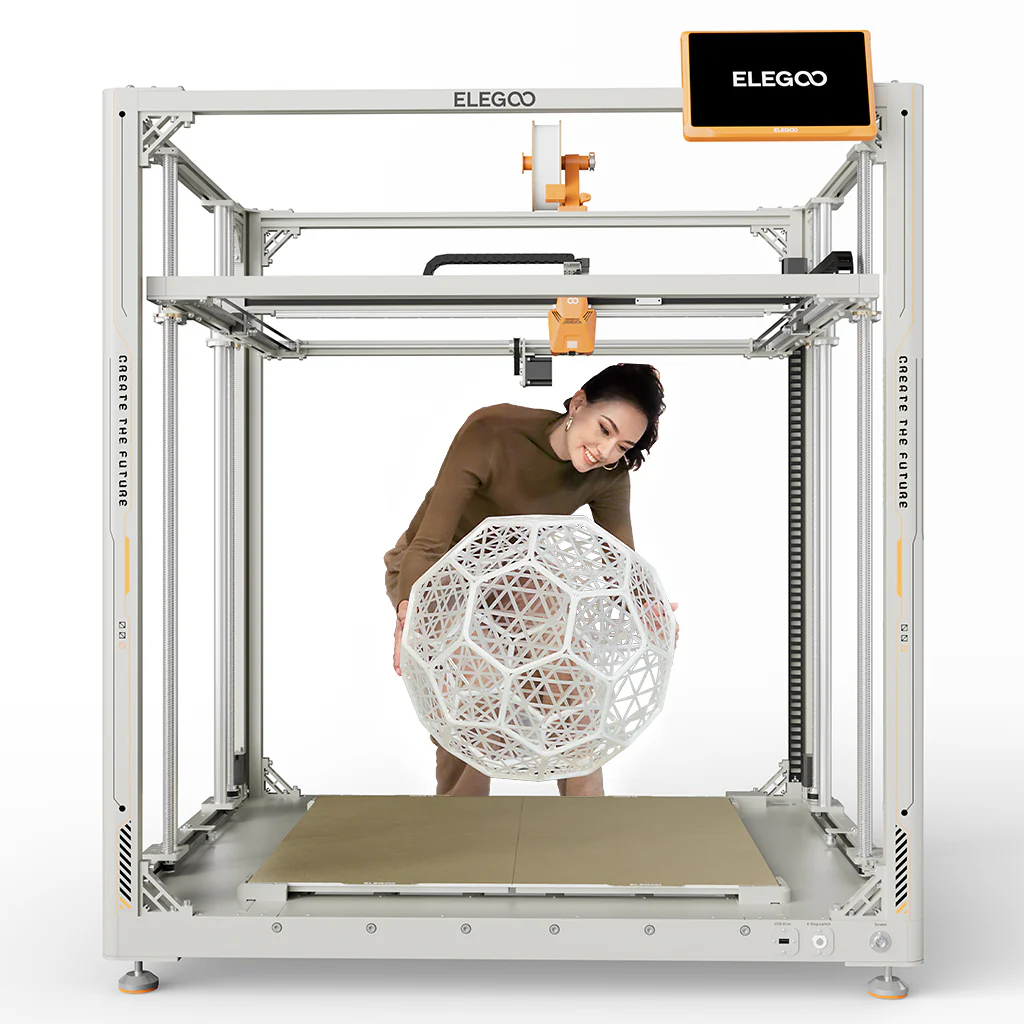

The Elegoo OrangeStorm Giga is no ordinary 3D printer. With its huge build volume of 800 x 800 x 1000 mm, it exceeds all dimensions that one is used to from home 3D printers. This colossus forms a bridge between hobby and professional use, and opens up completely new possibilities for ambitious makers.

Features at a glance:

- Robust construction in industrial quality,

- Build volume of 800 x 800 x 1000 mm,

- Heated bed with 4 independent PEI high temperature platforms,

- Automatic detection of the platform used and its individual heating,

- 64-bit quad-core high-performance processor for high-speed printing of up to 300 mm/s,

- Optional multi-nozzle printing with the possibility of attaching three additional print heads for multi-colour printing,

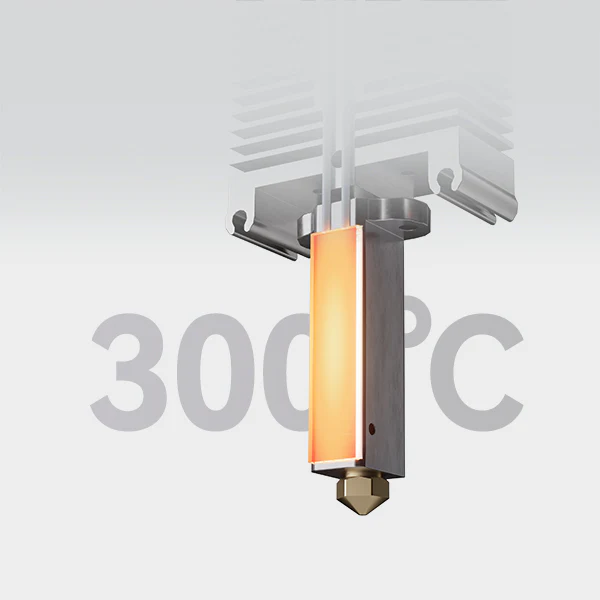

- Improved nozzle design for a printing temperature of max. 300 °C,

- Automatic PID calibration function for precise control of the nozzle temperature,

- Automatic one-click levelling and a contactless high-precision sensor ensure the flatness of the platforms,

- Special cable rails for durable cables,

- Filament detection and power loss recovery,

- etc.

A giant among FDM printers

The OrangeStorm Giga impresses with its gigantic build volume of an incredible 800 x 800 x 1000 mm. The industrial-grade 3D printer offers almost unlimited possibilities for carrying out huge projects without the need to print large-format models in several passes.

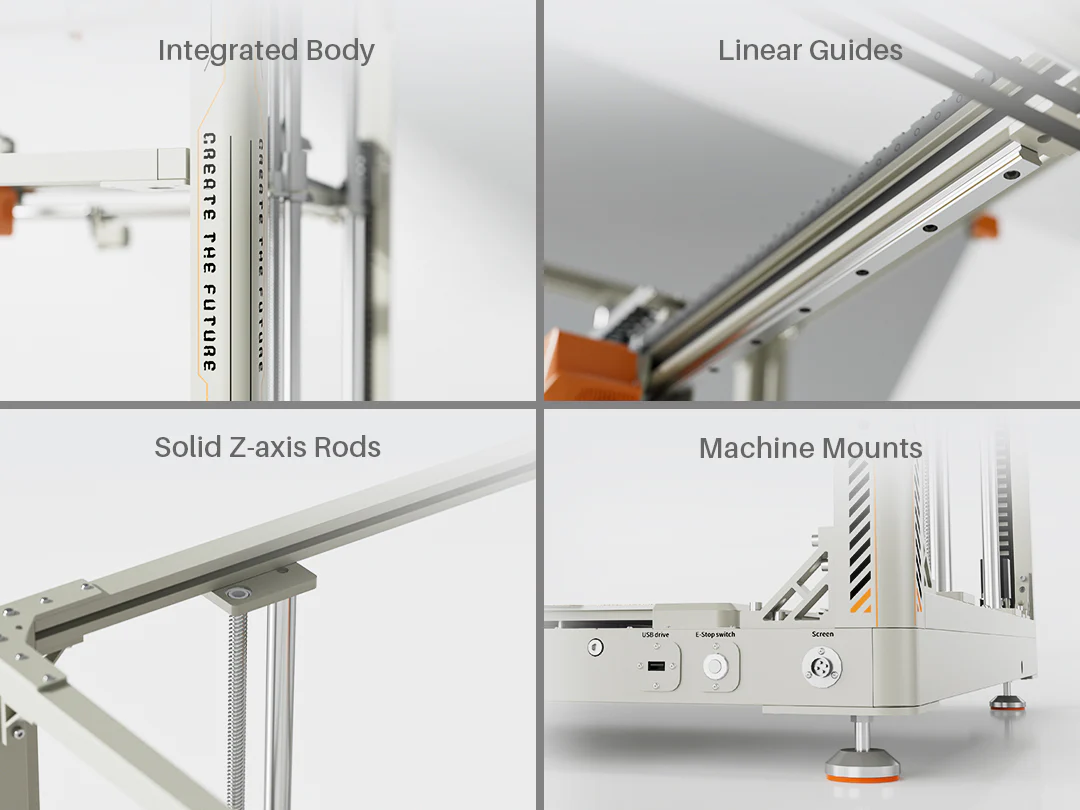

Robust construction

The FDM printer is designed for demanding use and impresses with its sturdy construction. The giant has an elegant and durable integrated housing; the X and Y axes are linear guides that effectively improve printing stability and extend the service life. The Z-axis has a robust guide rod that ensures smooth operation and precise levelling. The printer itself is equipped with round carbon bases with anti-slip rubber pads.

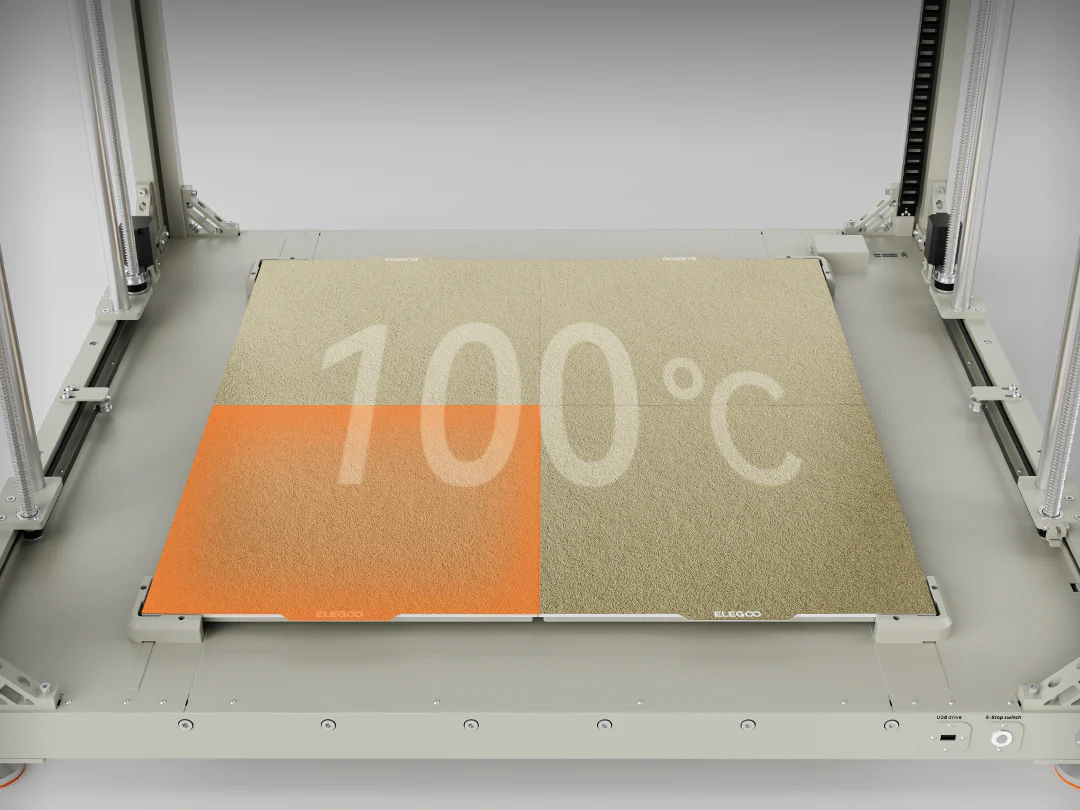

Bed with four independently heated platforms

The OrangeStorm Giga ‘s heatbed consists of four independent magnetic PEI build plates. These high-temperature platforms (each measuring 410 x 410 mm) are designed for a maximum temperature of 90 °C and can be heated simultaneously. They reach a temperature of 90 °C over the entire surface within approximately 17 minutes (at an ambient temperature of 25 °C).

Special sensors enable the platform on which the model is located to be automatically detected in order to heat it. However, the individual build plates can also be heated and controlled manually and independently of one another as required.

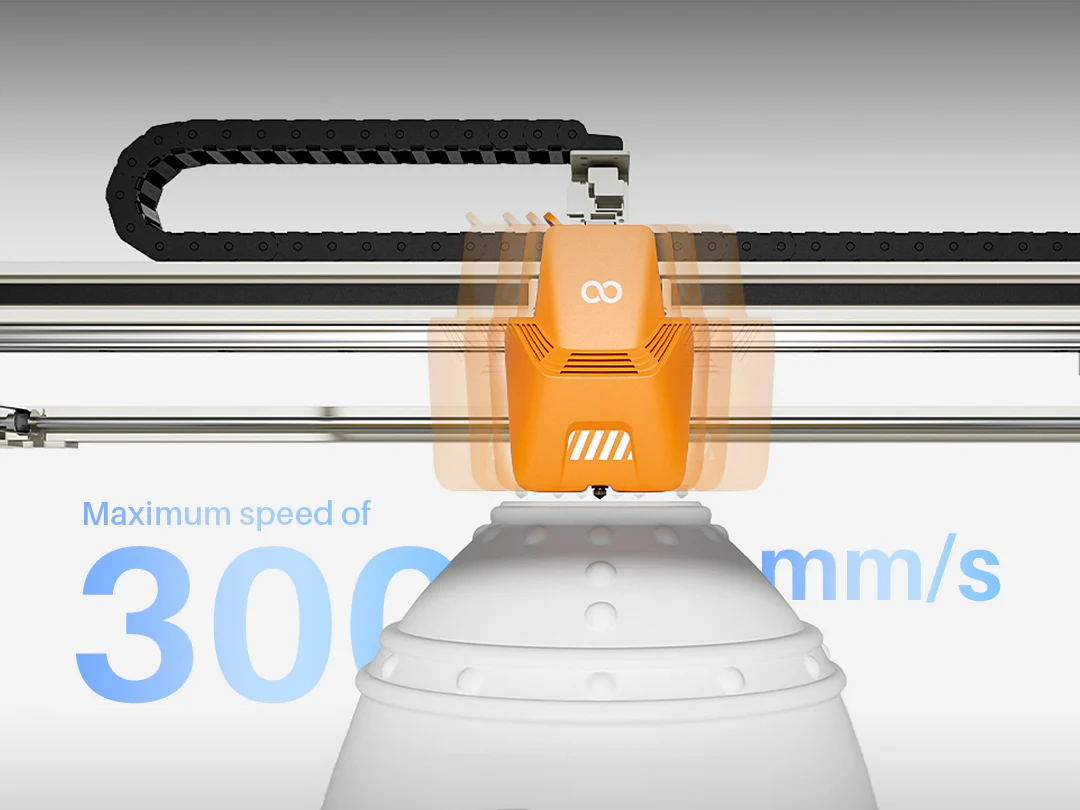

Rapid speeds

Thanks to a 64-bit quad-core high-performance processor (SOC RK3328) with a clock speed of 1.5 GHz, the gigantic printer achieves a printing speed 6 times higher than other 3D printers of this size:

- Max. printing speed of 300 mm/s,

- Recommended printing speed of 150 mm/s.

Multi-nozzle printing

The printer allows you to attach three additional print heads to the X-axis to print four models at the same time. In addition, you can use different coloured filaments of the same material to bring your printed objects to life with colour.

Improved nozzle design

The printer is equipped with an optimized nozzle designed for temperatures of up to 300 °C. The high-temperature nozzle made of chrome-zirconium-copper has a proximal double gear extrusion structure and a titanium alloy heat pipe, and has been upgraded with a 60 watt ceramic heating pad.

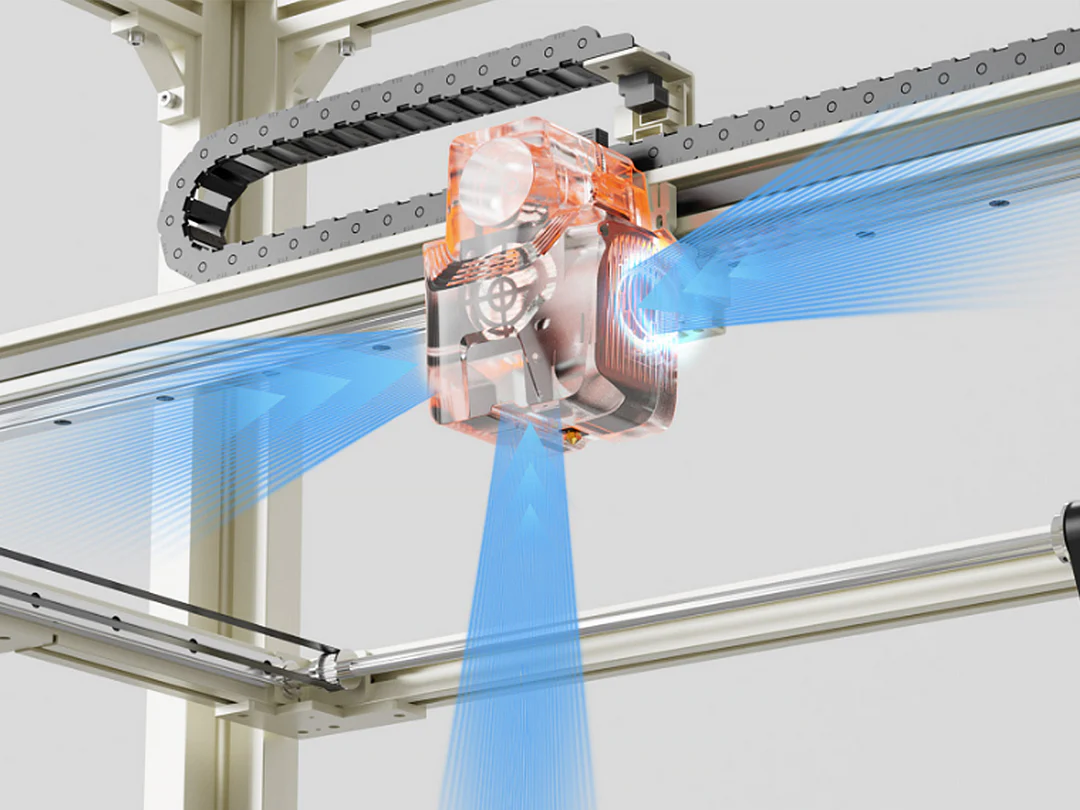

Powerful double-sided fans

The OrangeStorm Giga is equipped with robust double-sided cooling fans: 2 x 5015 ball fans, 1 x 4010 ball axial fan. These have an intelligent control function that automatically turns them off after the printing process is completed to save energy, reduce noise and extend the service life. This can achieve more uniform extrusion and higher printing precision.

By integrating an automatic PID calibration function, the nozzle temperature can be precisely controlled. To generate even better print quality, a built-in acceleration sensor automatically calibrates the parameters for resonance compensation.

Additional features:

- Automatic one-click levelling and a non-contact high-precision sensor collect platform data at 121 points to ensure that it is level,

- The printer’s cables are stored in special cable rails to protect them from external influences such as dust or contamination as well as from wear and tear and breakage,

- Automatic filament detection and power loss recovery,

- 7 inch HD capacitive touchscreen,

- User-friendly knob design,

- Practical spool holder made of sheet steel for spools up to 5 kg.

| Gigantic in SizeWith a build volume of 800mm x 800mm x 1000mm, the industrial-grade FDM printer not only meets the user’s printing needs for oversized models, but also reduces the need to cut models into smaller sections for efficient printing. |

Efficient Heated BedThe heated bed consists of four independent (410*410mm) PEI magnetic high-temperature platforms with a maximum temperature of 100°C. The four platforms can be heated simultaneously to reach 100°C over the entire area in 17 minutes (Ambient temperature: 25℃). The platform where the model is located can also be automatically recognized and heated independently, or manually and independently controlled for increased energy efficiency. |  |

| Fast PrintingUtilizing a 64-bit 1.5G clock speed quad-core high-performance processor (SOC RK3328), it provides sufficient computing capacity while delivering 6 times the printing speed, with a maximum speed of 300mm/s (150mm/s recommended), which is the top end print speed for printers of its size. |

Multi-Nozzle PrintingThree additional printheads can be added to the X-axis to realize simultaneous printing with four nozzles, supporting printing four of the same model, while each nozzle can be equipped with the same material and different color filament to achieve four different colored models of the same kind. |  |

| Powerful Cooling FanThickened double-sided cooling fans can comprehensively enhance the model printing results. In addition, the fans are equipped with an intelligent control function that stops working when printing is complete, which saves energy and reduces noise as well as prolongs the lifespan. (5015 ball blower fan*2, 4010 ball axial fan*1) |

High-Quality CraftsmanshipIntegrated body, elegant yet durable. The X-axis and Y-axis are linear guides, effectively improving printing stability and increasing lifespan. The Z-axis features an upgraded version of the Z-Axis rod to make the machine run smoothly and ensure leveling precision. Machine mounts are designed with a carbon steel round base and rubber round anti-slip pad bottom. |  |

| Upgraded NozzleThe upgraded 300℃ high-temperature nozzle adopts a proximal double-gear extrusion structure and full titanium alloy heat pipe. Plus, the nozzle is upgraded to chrome zirconium copper with a 60W ceramic heating pad for smoother and more uniform extrusion, which improves the printing precision. |

- Product Model: OrangeStorm Giga

- Printing Technology: FDM (Fused Deposition Modeling)

- Voltage: 100-120V/220-240V

- File Transfer Method: USB, LAN, WIFI

- File Format: STL, OBJ

- UI Language: English, French, German, Russian, Italian, Spanish, Japanese, Chinese

- Build Volume: 800 x 800 x 1000 mm³

- Printing Platform Size (PEI Area): 820 x 820 mm² (4 independent 410 x 410 mm² PEI plates)

- Machine Size: 1224 x 1164 x 1425 mm³

- Package Size: Bottom + XY Axis Components: 1350 x 1215 x 420 mm³

- Two Z-Axis Components: 1350 x 1215 x 350 mm³

- MAXIMUM SIZE FOR MACHINE ACTIVITY/MM: 1224 x 1520 x 1570

- Max. Nozzle Temperature: 300°C

- Max. Hot bed Temperature: 100°C (ambient temperature: 25°C)

- Filament Compatibility: PLA / PETG / TPU / Nylon

- Net Weight: 104kg

- Gross Weight: 145kg

- Resume Printing: Yes

- Filament Detection: Yes

- Max Speed of Tool Head: 300 mm/s

- Max Acceleration of Tool Head: 5,000 mm/s²

Based on 0 reviews

Be the first to review “Elegoo Orange Storm Giga Size FDM 3D Printer”

You must be logged in to post a review.

There are no reviews yet.