Buttons, Switches & Pads, Connectivity, Limit Switch

Limit Switch Large

- Bendable sheet metal switch “arm” is very versatile

- Useful as a trigger in a variety of applications

Availability:

In stock

₨ 50

In stock

Limit Switches

These limit switches closely resemble rugged toggle or selector hand switches fitted with a lever pushed by the machine part. Often, the levers are tipped with a small roller bearing, preventing the lever from being worn off by repeated contact with the machine part.

Limit Switch automatically monitor and indicate whether the movement limits of a particular device have been exceeded. A standard industrial limit switch is an electro mechanical device that contains an actuator linked to a series of contacts. When an object meets the actuator, the limit switch triggers the contacts to either form or break an electrical connection. Limit switches are commonly employed in a wide range of applications and under a variety of operating conditions due to their ease of installation, relatively straightforward design, ruggedness, and reliability.

Industrial machinery that undergoes automatic operations usually requires control switches that activate according to the movements involved in a machine’s performance. For repeat usage, the accuracy of the electrical switches needs to be reliable and their response rate should be prompt. Due to the mechanical specifications and performance parameters of different machines, factors such as size, operational force, mounting method, and stroke rate are important characteristics in the installation and maintenance of limit switches. In addition, a limit switch’s electrical rating should be matched to the mechanical system loads that it will be controlling in order to avoid instrument failure.

Limit Switch Operation

In most cases, a limit switch begins operating when a moving machine or a moving component of a machine makes contact with an actuator or operating lever that activates the switch. The limit switch then regulates the electrical circuit that controls the machine and its moving parts. These switches can be used as pilot devices for magnetic starter control circuits, allowing them to start, stop, slow down, or accelerate the functions of an electric motor. Limit switches can be installed into machinery as control instruments for standard operations or as emergency devices to prevent machinery malfunction. Most switches are either maintained contact or momentary contact models.

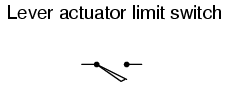

Limit Switch Contacts

Control schematics for limit switches usually display symbols to indicate the state of the switch contacts. The most common contact symbols show whether the device has normally open or normally closed limit switch contacts. The symbol for a “normally open held closed” state indicates that the contact has been wired as a normally open contact, but when the circuit is put into its normal off state, part of the machine keeps the contact closed. Likewise, a limit switch that is designated as “normally closed held open” will have a closed wiring design but be held open. Other types of contacts, such as those used in pressure and flow switches, can be configured in a similar way.

For illustrations and more detailed information on the symbols used for electrical contacts, visit Fundamentals of Electrical Engineering and Electronics.

Micro Limit Switches

The micro limit switch, or micro switch, is another type of limit switch commonly found on control circuits. These switches are much smaller than their standard counterparts, allowing them to be installed in narrow or cramped spaces that would normally be inaccessible to other switches. Micro switches usually have an actuating plunger that only has to travel a small distance in order to trigger the contact sequence. The actuating plunger is often found at the top of the micro switch, and must be depressed a predetermined amount before it activates. A small degree of movement is able to change the contact positions due to a spring-loading mechanism that causes movable contacts to snap between alternating positions. Micro switches can be designed with a range of different activating arms, and have contacts with electrical ratings that are usually around 250 volts of alternating current and between 10 to 15 amperes (amps).

Much like micro limit switches, subminiature micro switches are intended for use in applications requiring compact designs and limited space availability. They have contact arrangements with spring-loading mechanisms similar to those of micro switches, but tend to be from one-half to one-quarter the size of regular micro switches. Depending on the particular model, subminiature switches have contacts with electrical ratings ranging from about 1 to 7 amperes due to the reduced size of the switches themselves.

Based on 0 reviews

Be the first to review “Limit Switch Large”

You must be logged in to post a review.

There are no reviews yet.